Slurry Sampler

A Proven Method

RSI's slurry sampling system is designed to collect representative samples of two phase, solid/liquid material flowing in process piping.

Background

Sampling of slurries is a difficult and dose intensive task. If the composition of the sample stream changes, a single sample of the process can lead to improper characterization. This could lead to incorrect waste assay. The utility may over- or under-pay for shipping and burial costs based on this single sample. The use of RSI's slurry sampler ensures that a representative sample is collected.

Application

Sampling ion exchange resins during transfer between the condensate demineralizers and the resin regeneration facility, sampling during transfers from spent resin tanks to a liner, sampling the inlet and effluent streams of ultrasonic resin cleaners, and sampling radwaste process streams.

Description

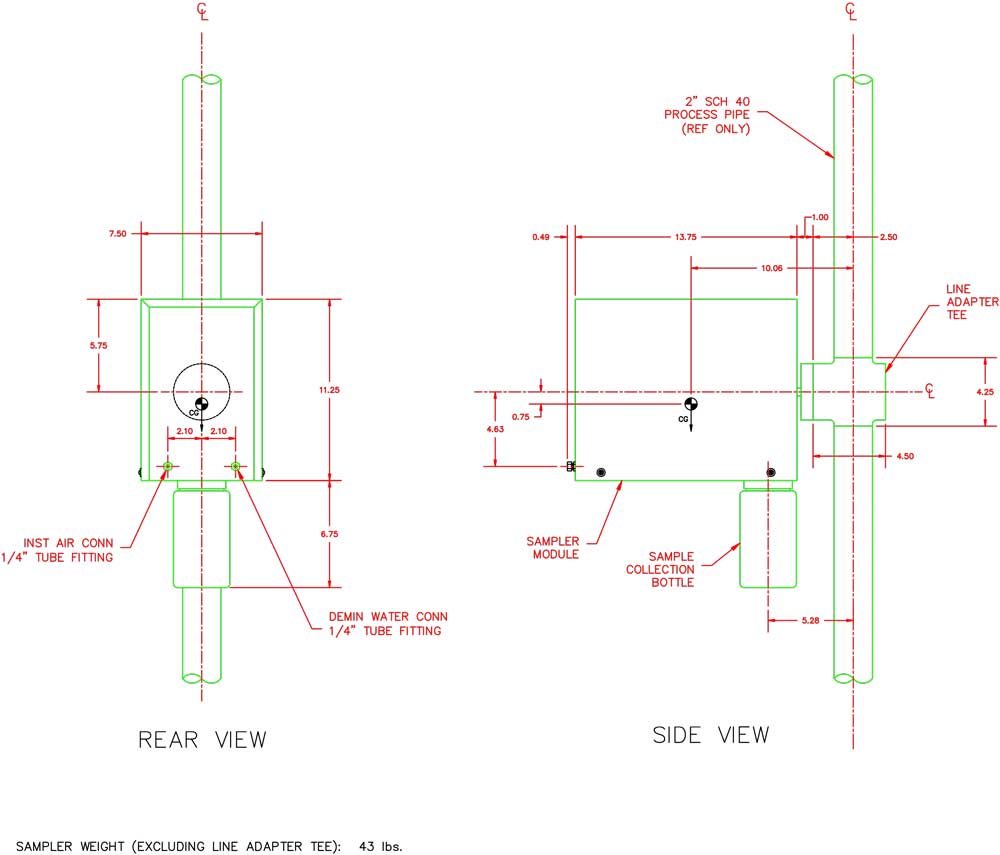

The RSI slurry sampling system consists of a microprocessor-based controller and a remote sampling module. This allows for remote sampling and low operator exposure even when collecting high dose rate sample streams. Interconnection of the controller and sampling module is made with a seven-wire multi-conductor cable. The controller and sampling module may be up to 250 feet apart to enable locating the controller in a low dose rate area. The sampling module can be installed in most types of piping arrangements. The RSI slurry sampler is pneumatically driven by a 4 way solenoid valve housed in the sampling module. During sampling, the sampler's plunger is periodically extended into the process stream and then retracted to capture a 10 cc sample aliquot. Sampler operation is automatically repeated at equal time intervals throughout the sampling period until the total number of cycles specified by the user have been completed. With appropriate input of the number of cycles and the interval between cycles, a representative sample is obtained from a process stream even if its composition changes during the sampling period. To provide a smooth unobstructed flow path, the sampler's plunger always remains retracted except when actually collecting a sample aliquot. When the plunger is retracted from the process pipe, the captured sample aliquot is discharged into the collection bottle suspended directly beneath the sampling module. The recessed area of the plunger's spool piece in which the sample was captured is subsequently flushed using air, water, or both to completely transfer the sample aliquot into the collection bottle. After each sampling operation, the operator should exchange the sample collection bottle with a fresh one. This task typically requires approximately 15 to 30 seconds for completion.

Unique Features

The RSI slurry sampler allows for:

- Representative sample collection

- Simple operation

- Reduced Operator exposure

- User definable sampling parameters

- Easy plant retrofit

Summary

The industry proven slurry sampler is a system developed by RSI to allow for collection of representative slurry samples. Accurate sampling is required to ensure a proper assay of waste for packaging, shipping and ultimately for burial. This unique product has proven to be simple to install, easy to operate and will help meet ALARA goals.