Noble Metals Sampling

VERIFY ON-LINE NOBLE CHEM™ DEPOSITION AND CLAIM INSPECTION RELIEF WITH NOBLE METALS SAMPLING

Introduction

The majority of domestic boiling water reactor (BWR) plants have implemented Noble Metals Chemical Application (NMCA) or have transitioned to On-Line NobleChem™ (OLNC). Noble metals deposited on reactor internal components are believed to deplete over time due to mechanical shear forces from fluid flow passing over the surfaces. The need to re-apply noble metals is commonly based on depletion rates of pre-oxidized stainless steel tubing coupons located in a durability monitor (DM) or Mitigation Monitoring System (MMS). Coupons are periodically removed from the MMS by the utility and sent to an off-site laboratory for noble metals analysis. The MMS is located on the reactor water cleanup (RWCU) inlet piping and there is speculation as to the representation of the sample point at limiting noble metals conditions. The amount of noble metals deposited on the deposition monitor and durability monitor has varied widely during NMCA and OLNC. Minor changes in reactor coolant pH and/or temperature result in different deposition rates. Artifact or direct sampling of the core shroud has been used at plants when DM or MMS data has been questionable. Plants must show that the noble metals deposition is >0.1 µg/cm2 to claim inspection relief in accordance with BWRVIP-62A, “Technical Basis for Inspection Relief for BWR Internal Components with Hydrogen Injection.”

Sampling Services

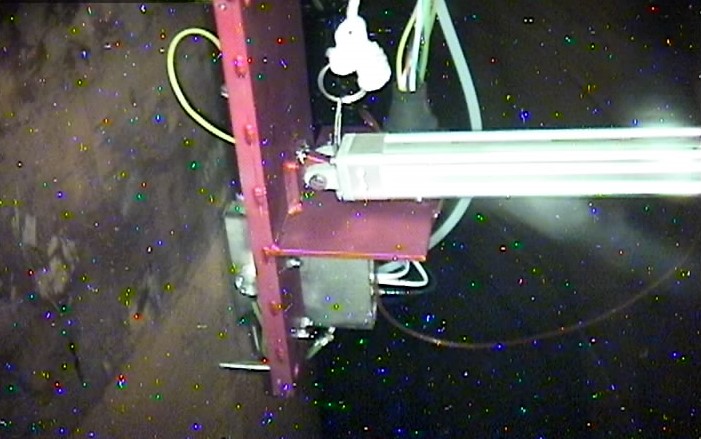

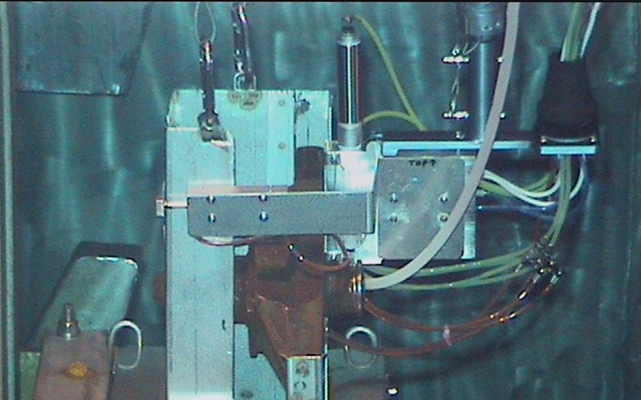

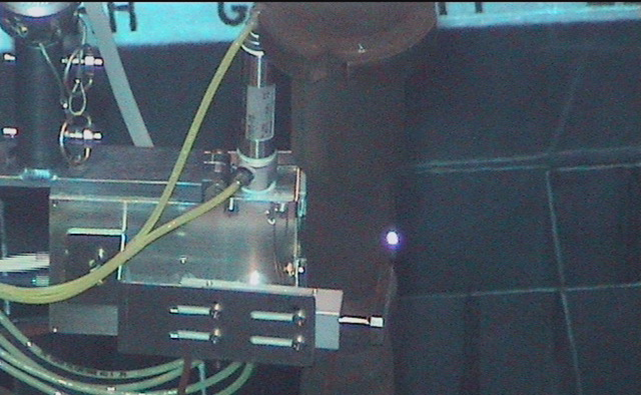

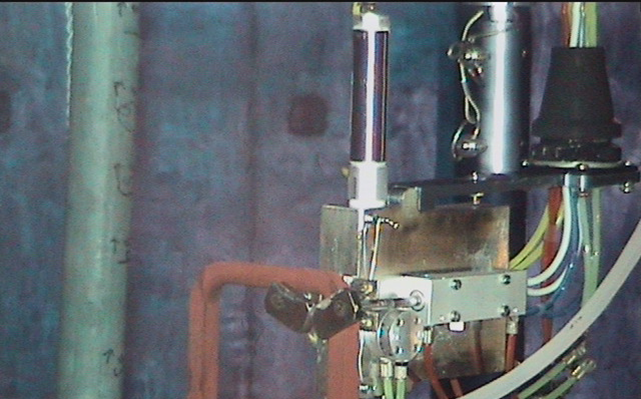

RSI noble metals corrosion deposit sampling systems are adaptable to obtain samples from many types of surfaces and is based on fuel deposit sampling technology that has been used for more than 30 years. EPRI BWRVIP sampling equipment can be shipped to the plant or RSI can fabricate dedicated sampling equipment for use at single site (eliminates costly radioactive material shipments). RSI engineers perform the sampling and provide the samples to plant personnel for shipment to contract laboratory that has been qualified by the BWRVIP program for analysis of Pt and Rh. Detection limits are typically below 0.01 µg/cm2.

Experiences

RSI has collected noble metals samples from the following surfaces:

- Fuel Channel Clips (sampling can be done non-outage in the spent fuel pool) (CGS)

- Core Shroud Outside Diameter near the H4 weld (CGS, LCGS, DAEC, PBABS)

- LPRM Tubes (LCGS, GGNS)

- Surveillance Capsules (PNPP, BFS)

- Fuel Channels (PNPP)

- Lifting Bale (PNPP, LCGS)

- Jet Pump Beams, Shroud Head Bolts (LCGS)