Advanced Resin Cleaning System (ARCS)

A Proven Method

The Advanced Resin Cleaning System (ARCS) was developed in the late 1980s by members of Radiological Solutions, Inc. This system, which has been successfully operated for many years in both Boiling Water Reactors (BWRs) and Pressurized Water Reactors (PWRs), is extremely efficient for removal of both insoluble corrosion products and anion/cation resin fines. The system also generates significantly less waste water than other cleaning methods.

Unique Features

- Allows for dramatic reduction in feedwater insoluble iron

- Potential to extend usable resin life

- Reduces waste water to less than 30 gallons per cubic foot of resin cleaned

- Decreases resin bed differential pressures

- Eliminates resin "fines" from bed

- Reduces operator time and exposure

- Minimizes equipment maintenance

Background

Power plant steam generation systems can undergo serious material degradation by a variety of corrosion-related phenomena. These phenomena are largely controlled by boiler water (i.e. reactor water) chemistry which is strongly impacted by the performance of the condensate system mixed bed ion exchange units. These ion exchange units not only provide protection from ionic contaminants, but also remove insoluble corrosion products by filtration/adsorption. The insoluble corrosion products removed by ion exchange units must be periodically cleaned from the resin bed by some external process.

Application

The ARCS is used to perform routine cleaning of condensate ion exchange resins in electric power generation stations. The ARCS, which is easily retrofitted into existing plants, allows plants to meet optimum water chemistry guideline feedwater iron concentrations. In BWR’s, this results in person rem exposure reduction as well as cost savings associated with zinc injection.

Description

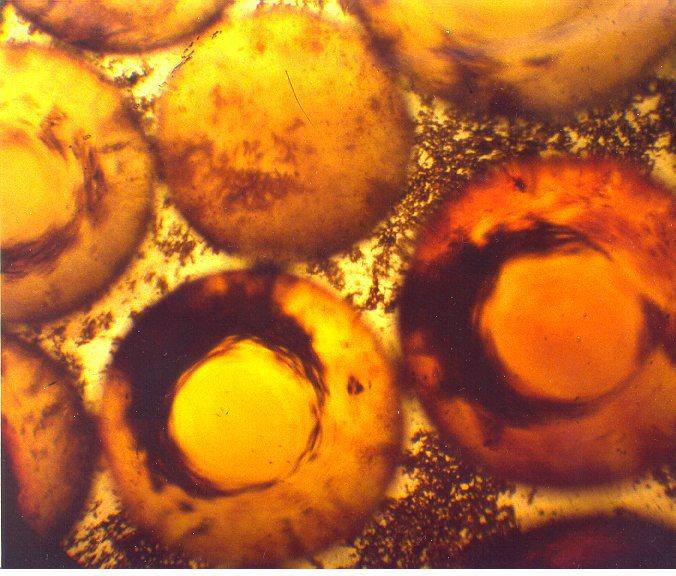

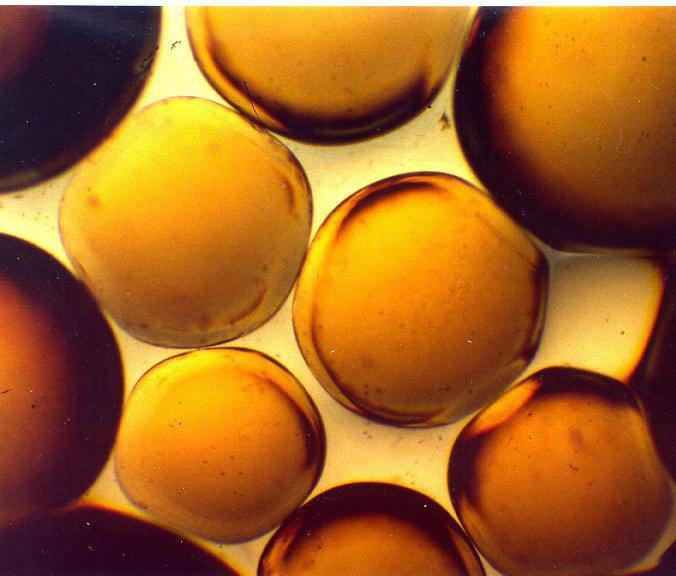

Typically, a resin bed is transferred from the service vessel to a receiving tank (i.e. Cation Regeneration Tank). From this tank, the resins are educted to the ARCS which incorporates a vibrating screen assembly containing a coarse and a fine screen in series. The coarse screen de-waters the resins and allows any loose corrosion products and resin fines to be directly separated from the resin bed. As the whole resin beads traverse the vibrating screen assembly, a high pressure spray of water removes any, more tightly adherent corrosion products on a nearly bead-by-bead basis. The resin fines, which passed through the coarse screen, are subsequently retained on a second screen with smaller openings where they are dewatered and discharged into a separate "Fines Container" for eventual waste disposal. The high pressure spray water and the cleaned resin transfer water are continuously recycled to minimize the volume of wastewater generated by the process.

Flexible Installation

The ARCS is modular for installation flexibility and is typically comprised of multiple skids. An example of one such installation follows:- Electrical Skid containing an electrical load center and microprocessor control panel

- Clean Resin Skid containing a clean resin tank, transfer water tank, clean resin transfer pump, and clean resin eductor

- Spray Water Skid containing a spray water tank, a spray water pump, and a spray water flow controls

- Screen Skid containing a vibrating screen assembly